|

|

MODEL HBS-3000TE

TOUCH SCREEN DIGITAL DISPLAY

BRINELL HARDNESS TESTER

Feature & Use

-

Electric loading without weights, closed loop

control.

-

Large 8” touch screen, direct visual display and

interactive operating interface.

-

High speed ARM processor, fast operation speed

and extensive database storage.

-

High quality integral casting cast iron machine

body with automotive paint treatment process, the appearance is smooth and

beautiful.

-

Built-in hardness conversion scales, which can

realize full hardness scale conversion.

-

The maximum and minimum hardness values can be

set, when the test value exceeds the set range, an alarm sound will be

issued.

-

Automatic hardness value correction, the

hardness value can be directly corrected within a certain range.

-

With the database function, the test data can be

saved automatically in groups, each group can save 10 data, totally can save

more than 2000 data.

-

With the hardness value curve display function,

intuitively display the changes of hardness value.

-

Equipped with wireless blue-tooth printer, the

data can be output through RS232 or USB interface.

-

CCD image processing system or video measuring

apparatus is optional.

-

Precision conforms to GB/T 231.2, ISO 6506-2 and

ASTM E10

It’s

suitable to determine the Brinell hardness of unquenched steel, cast iron,

non-ferrous metals and soft bearing alloys, etc.

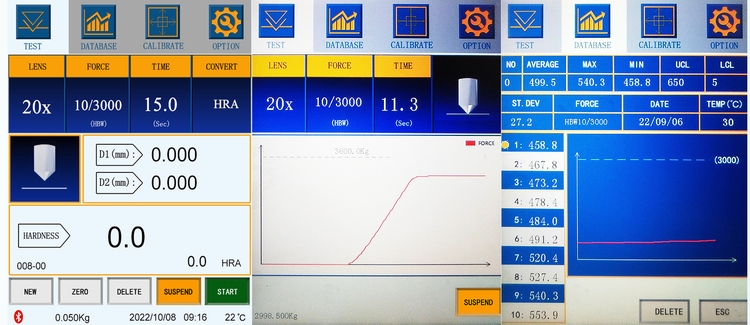

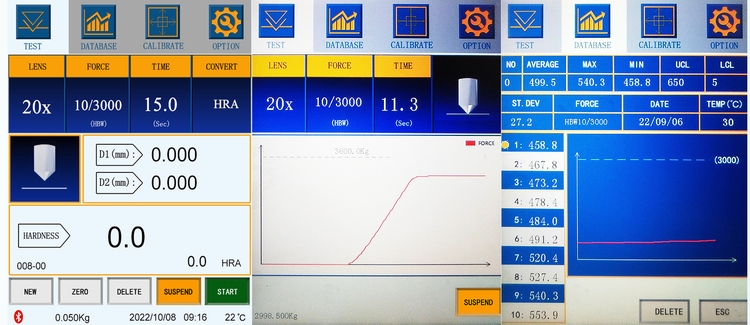

Main interface

Specifications

Measuring range: 5-650HBW

Test force: 62.5, 100, 125, 187.5, 250, 500, 750,

1000, 1500, 3000kgf

(612.9, 980.7, 1225.9, 1838.8, 2415.8, 4903.5,

7355.3, 9807, 14710.5, 29421N)

Hardness resolution: 0.1 HBW

Min. measuring unit: 5μm

Eyepiece magnification: 20X

Objective lens magnification: 1X

Total magnification: 20X

Max. height of test piece: 280mm

Depth of throat: 165mm

Dwelling time: 1~99s

Power supply: 220V AC or 110V AC, 50 or 60Hz

Dimensions: 700 x 268 x 930mm

Weight: approx. 160kg

Standard accessories

Large flat anvil: 1 pc.

Small flat anvil: 1 pc.

V-notch anvil: 1 pc.

Tungsten carbide ball penetrator: Φ2.5, Φ5, Φ10mm, 1

pc. for each

Brinell standardized block: 2 pcs.

|

|