|

|

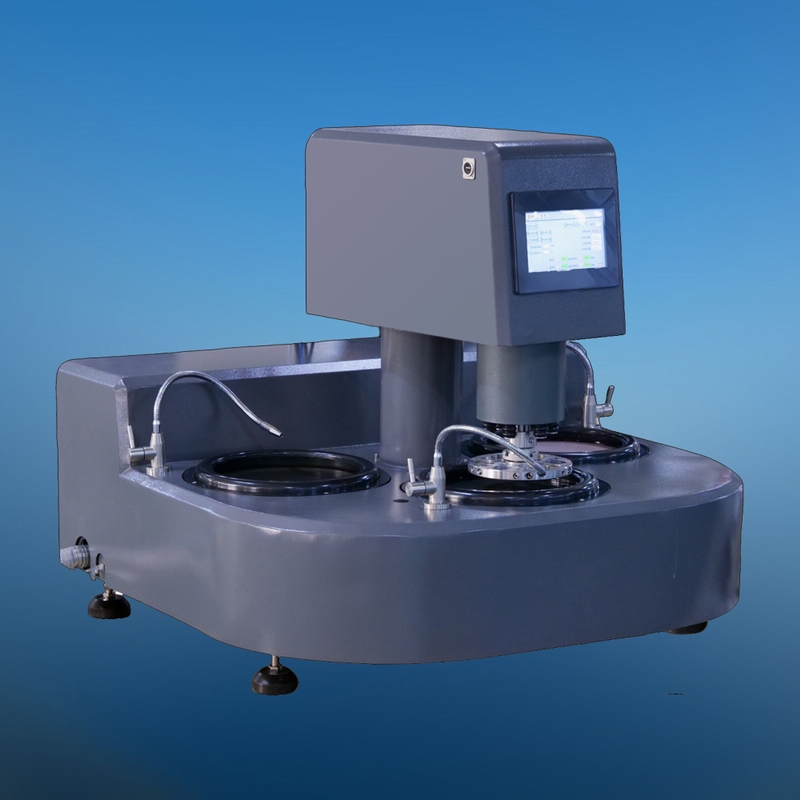

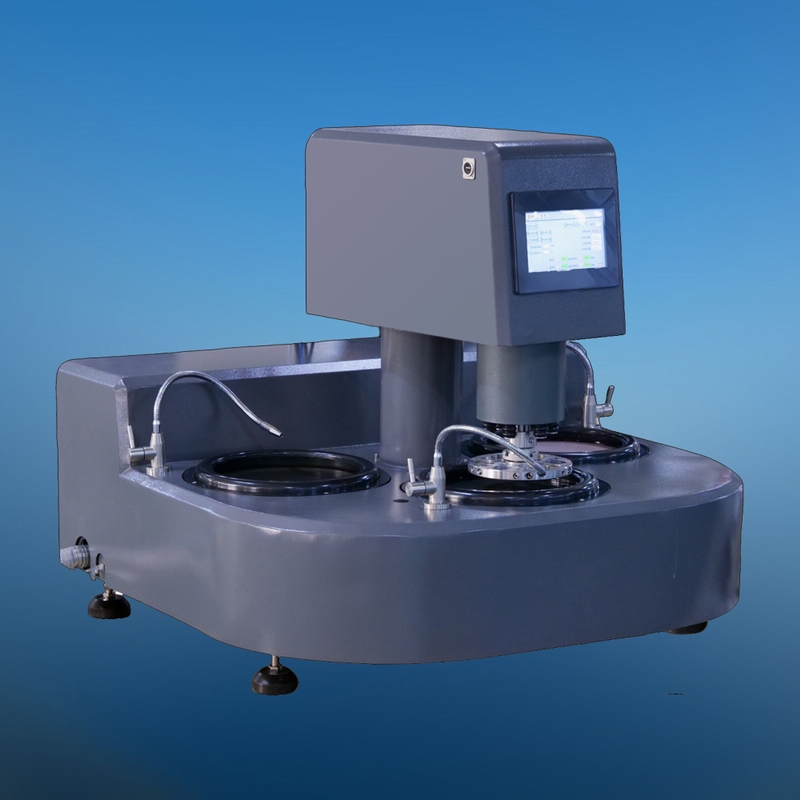

MODEL

AUTOPOL 3000Z

TOUCH

SCREEN THREE-DISC AUTOMATIC GRINDING & POLISHING MACHINE

Features

-

For simple samples, they can be obtained with

just one click.

-

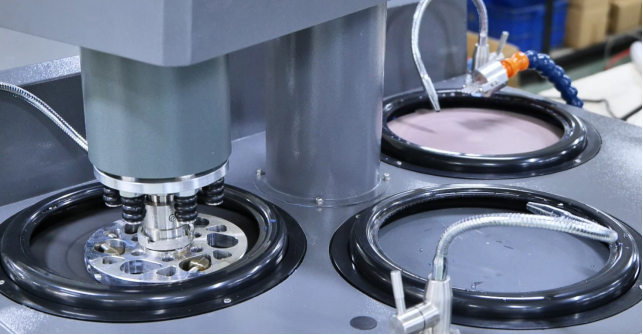

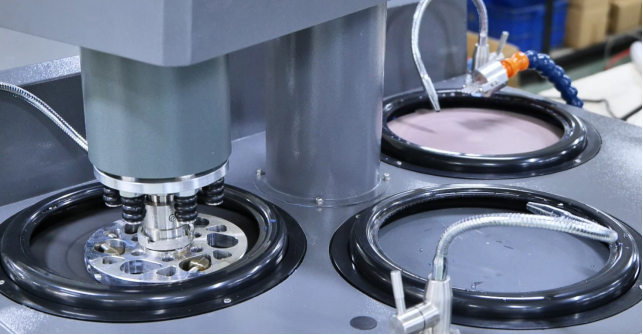

After the sample holding disc is grinded or

polished on the first disc, it can automatically switch to the second and

third polishing discs for grinding or polishing.

-

The sample holding disc can automatically swing

left and right on each grinding and polishing disc, with adjustable swing

amplitude and speed.

-

Single loading method for multiple samples.

-

Central force loading method (Optional): Fix six

samples at once time to complete the entire grinding and polishing process,

ensuring the complete flatness of each sample during grinding.

-

Working modes:

(1) Fully automatic mode:

According to the sample materials or user habits, 99

sets of processes (processes) can be set and called, each set of processes can

contain 10 process parameters (process parameters for each step of grinding or

polishing process: grinding disc and grinding head rotation speed, grinding and

polishing time, etc.)

(2) Multi process mode:

According to each grinding and polishing process, 30

process parameters can be set and called: grinding disc and head rotation speed,

grinding and polishing time, water on/off, etc.

(3) Multiple working modes: fully automatic, multi

process, manual.

-

Grinding and polishing disc and sample disc: Set

and operate all grinding and polishing parameters such as speed, polishing

time, rotation direction, and water valve closure, and automatically save

them for easy access.

-

Adopting PLC+1KW high-power servo motor, the

torque of the 1KW high-power servo motor is large and constant regardless of

the speed.

-

Wide speed range, from 0 revolutions per minute

to 1500 revolutions per minute.

-

Quick start stop of the turntable, the turntable

can stop rotating in 2 seconds.

-

All grinding and polishing parameters such as

speed, grinding and polishing time, rotation direction, and water valve

closure can be automatically saved and easily accessed.

-

Touch screen interface, convenient for setting

grinding and polishing parameters.

-

1 or 4 or 6 channel automatic dripper

(Optional):

(1) The main unit of the grinding and polishing

machine controls the four-channel dripper, and the type and speed of the dropper

are instructed by the grinding and polishing machine.

(2) The dripper has three working modes: manual,

online, and fully automatic.

(3) Connect to the polishing machine and drip

according to the grinding and polishing parameters set by the grinding and

polishing machine. Each mode can be set independently: drip speed, drip time.

-

With the easy replacement of the magnetic

anti-sticking plate, all processes such as rough and fine grinding and rough

and fine polishing of various samples can be completed, with one plate

equivalent to N plates.

-

The loading force can be adjusted during

operation, which is flexible and convenient.

-

Control the on/off of water by using solenoid

valves.

-

Multi-language interfaces.

-

Mobile remote control operation (Optional)

-

Sample grinding layer thickness

control (Optional): Precisely control the amount of the sample to be ground

to the designated position .

-

External dropper control (Optional): Dripping

speed and material of the external dropper.

Technical

specifications

|

Model |

AUTOPOL 3000Z |

|

Workstations |

Three discs |

|

Loading force method |

Loading multiple samples separately

Center force loading

(Optional) |

|

Grinding disc diameter |

Standard with φ254mm (optional φ230mm, φ203mm)

with magnetic conversion disc system |

|

Grinding

disc speed |

0-1500

rpm, can

be switched between forward and reverse rotation |

|

Sample disc speed |

30-200

rpm,

can be switched between forward and reverse rotation |

|

Sample

holding disc |

Standard with Ø30mm six holes

(Optional Ø20 six-hole, Ø40 six-hole,Ø50mm three-hole.

the rest can be customized) |

|

Loading force range |

30-200N |

|

Manual mode |

30

groups of parameters can be selected, each set and invoked separately |

|

Auto

Mode |

99

sets of processes (flows), each set of processes containing 10 process

parameters

(Automatically from Process 1 to process 10, each process has a separate

set of parameters) |

|

Grinding

disc

motor power |

1000W |

|

Power supply |

AC 220V, 50/60Hz, 2KW |

|

Dimensions

(L*W*H) |

1000 x 900 x 800mm |

Standard

accessory

|

Name |

Quantity |

Name |

Quantity |

|

Grinding disc |

3 |

Gripper |

1 set |

|

Waterproof ring |

3 |

Power

adapter |

1

wire |

|

Data

adapter cable |

1

wire |

Touch

pen |

1 |

|

Mounting stand |

1 |

Sandpaper with adhesive (250mm)

1000# |

10

sheets |

|

Sandpaper with adhesive (250mm)

320# |

10

sheets |

Diamond suspension polishing liquid 6 microns 200ml |

1

bottle |

|

Velvet with self-adhesive polishing cloth (250mm) |

1

sheet |

Magnetic work plate (250mm) |

3

sheets |

|

Anti-sticking plate (250mm) |

3

sheets |

Anti-sticking plate

prying tool (for placing and prying up anti-sticking plates) |

1 |

|

Polishing lubricating coolant blue 200ml |

1

bottle |

Technical documentation:

1. User manual

2. Product qualification certificate |

One

copy each |

Optional

Accessory

-

Sample

grinding layer thickness control module: Resolution accuracy 0.01 mm

-

1-4-6-channel

automatic dropper

-

Mobile

remote control operation module

-

Common

consumables:

|

Metallographic

grinding paper |

GSC250A |

-

100 pieces /package

-

Material: black

carborundum

-

Sand size: P80# 120#

180# 320# 600# 800# 1000# 1200# 1500# 2000#

-

Size: Φ250mm

-

Waterproof and one

side sticky, can be attached on the grinding plate directly

|

|

Anti-sticky disc |

MAGNOMET |

-

Anti-sticky disc:

5 pieces/box

-

Diameter: Φ250mm

-

Surface coating with

Special anti-sticky layer, can attach the sticky paper and polishing

cloth directly, and easily replace without sticky mark.

-

Can be reused

|

|

Polishing cloth |

FT250A |

-

Polishing cloth

10 pieces/package

-

Velvet fabric (long

floss) / canvas (short floss)/ Woolen cloth (short floss) / silk

cloth (no floss)

-

Φ250mm

-

One side sticky, can

be attached directly on the grinding plate

|

|

Diamond grinding and polishing liquid |

DSU |

-

Diamond grinding and

polishing liquid, 500ml/bottle

-

Diamond suspending

in the liquid, can be dropped automatically or watering pot,

Uniformly distribution

-

Size: 0.25, 0.5, 1,

1.5, 2.5, 3, 3.5, 5, 6, 7, 9, 10, 14, 15, 20, 28, 40micron, for

different material

|

|

|