|

|

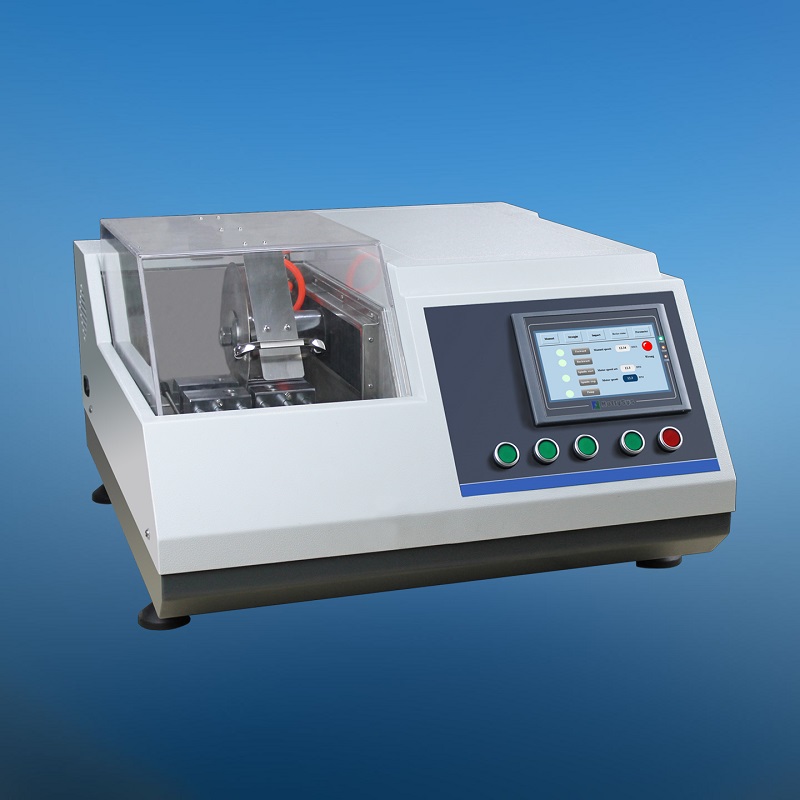

MODEL GTQ-5000B AUTOMATIC

HIGH SPEED PRECISION METALLOGRAPHIC SPECIMEN CUTTING MACHINE

Model GTQ-5000B Precise specimen cutting machine

can be used to cut material, electronic element, electronic element, crystals,

hard alloy, rock sample, core sample, concrete, organic materials, biological

materials (teeth, bones), etc. It applies precise cutting without deformation.

The device features high-power servo motor driving, high locating accuracy,

large range of speed, high cutting power, internal circulation cooling system,

pre-install feed speed, menu control and liquid crystal display, etc. The users

are free to define the cutting method. It is an ideal precise cutting machine

which can be used in industrial and mining enterprises, scientific research

institutes to prepare high quality samples.

Main features

-

It adopts HMI interface and PLC control, with

intuitive interface and simple operation.

-

The language can be switched between Chinese and

English, with simple operation and convenient parameter setting.

-

The spindle adopts servo motor closed-loop

control and overload protection.

-

There are two kinds of cutting methods to select

cutting, which can adapt to the cutting of various materials in a wider

range.

-

The setting parameters can be stored, and the

user can save the parameters for cutting different materials, and it is not

necessary to reset the parameters each time.

-

There is external circulating water cooling

device.

-

The closed transparent protective cover and

safety switch provide protection for the operator.

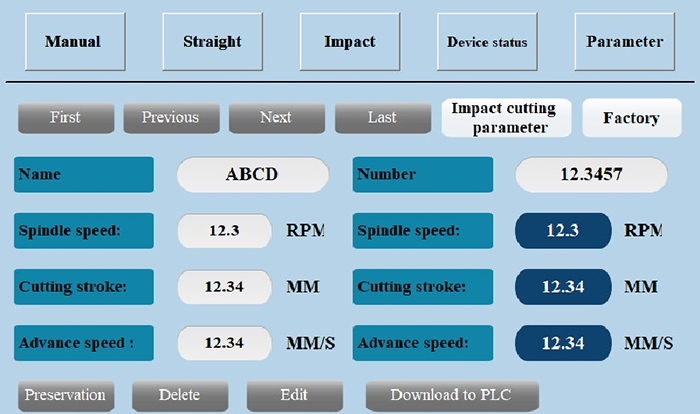

User interface

Parameter setting

-

Spindle speed: the user can set the speed

between 500-3000 rpm (500-5000 optional) to adapt to the material cutting,

and the setting is effective when the stepless speed regulation is running.

-

Cutting stroke: within the range of 0-200 mm,

set an appropriate stroke to stop cutting after cutting, and continuously

cut the same sample without new positioning.

-

Cutting speed: the range is 0.01-3mm/s, the

cutting speed suitable for materials is selected to meet the requirements

for material cutting, and the setting is invalid during operation.

-

Back speed: the range is 0-15mm/s, which refers

to the speed at which the cutting moves back to the starting point when the

cutting runs to the set distance. The larger the setting is, the faster it

will be.

-

The inching speed: the range is 0-15mm/s, which

refers to the manual forward and backward speed. When the equipment

operation is not proficient, it should be set smaller to avoid the cutting

blade hitting the workpiece.

-

Cutting mode selection: direct cutting and

impact cutting are two modes for users to choose, which can meet the needs

of material cutting in a wider range.

-

Direct cutting: it is the common and most

economical cutting mode, suitable for most material cutting options.

-

Impact cutting: it is applicable to certain

specific materials and materials with high hardness that cannot find the

appropriate cutting blade, and the worn material is easy to block the

cutting blade, or the abrasive of the cutting blade is insufficient. Impact

cutting may lead to higher cutting blade wear, but it will reduce the risk

of overheating of work pieces.

-

Cutting distance: the range is 0.1-2mm, which is

only effective for impact cutting mode. The smaller the set distance is, the

faster the impact cutting speed is. The cutting speed of work piece is

related to the set cutting speed.

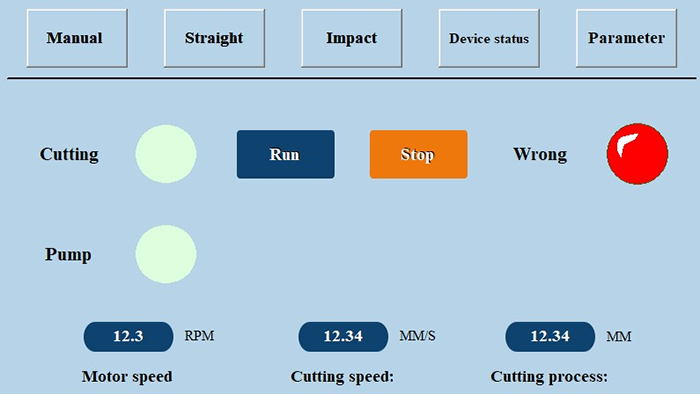

Operation interface:

Main Technical Specifications

-

Max cutting diameter: Φ60mm

-

Cutting wheel: 200 x 0.9 x 32mm

-

Main shaft rotating speed: 500~3000rpm (500~5000

rpm optional)

-

Feeding speed: 0.01mm~3mm/s

(increment of 0.01mm)

-

Manual feeding speed: 0~15mm/s

-

Withdraw speed: 0~15mm/s

-

Impact cutting distance: 0.1mm~2mm

-

Maximum stroke: Y-axis 200mm

-

Maximum clamping length of clamping vice: 150mm

-

Maximum clamping width of clamping vice: 200mm

-

Servo motor power: 1100W

-

Using method data storage: 12 kinds

-

Power source: single phase, AC 220V, 50Hz

-

Overall Dimension: 860 × 750 × 430mm

-

Weight: approx. 126 KG

Standard accessories

|

Item |

Quantity |

|

Cooling system (including

water tank, water pump, inlet pipe, outlet pipe) |

1 set |

|

Open-end spanner (22-24,

17-19) |

1 pc. for each |

|

6mm inner hexagon spanner |

1 pc. |

|

5mm inner hexagon spanner |

1 pc. |

|

Cutting lubricant liquid (1L) |

1 pc. |

|

Pipe clamper 13-19 |

2 pcs. |

|

Pipe clamper 40-63 |

2 pcs. |

|

Φ200mm diamond cutting disc |

1 pc. |

|

Power cord |

1 pc. |

|

|