|

|

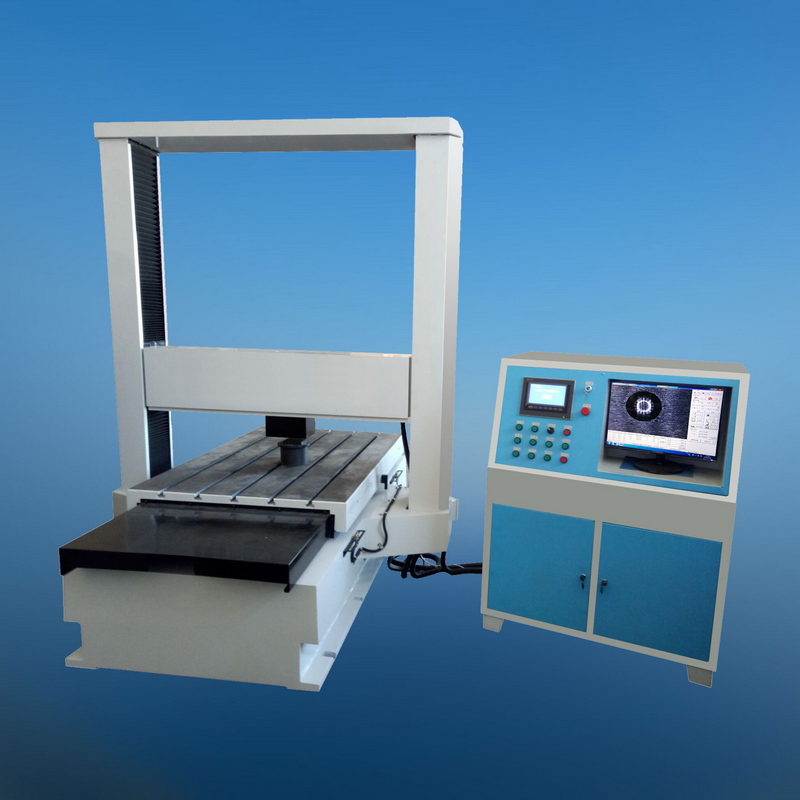

MODEL HBMS-3000E

GATE TYPE DIGITAL DISPLAY BRINELL HARDNESS TESTER

Feature & Use

-

The machine body

and worktable adopt precision casting technology, which is firm, rigid,

accurate, reliable and durable.

-

Precise work

piece positioning device to meet the accurate positioning of test point.

-

The

pre-processing milling operation is completed automatically, remove the

surface interference, the milling depth is consistent and adjustable

(Optional).

-

The loading

device has built-in precision pressure sensor, the test force value is

accurate, stable and reliable, and has the function of automatic test force

compensation.

-

Adopt the

self-developed gate-type Brinell hardness tester special numerical

controlling system, fast running speed, full closed loop from fast to slow

gradient applied test force, ensure the test force exerted smooth and no

impact.

-

Test force,

holding time, feeding speed and testing speed can be controlled manually.

-

There are

multiple sensors in whole process of online work, automatic completion of

the Work-Piece in & out and hardness test, no need for human on duty.

-

Automatic testing

process, which eliminates the human operating interference and reading

error.

-

Stepping motor,

high precision ball screw and linear guide rail, accurate positioning, easy

maintenance.

-

Equipped with

automatic Brinell CCD image measuring system, the image processing module

can take the closed snapshot of indentation, automatically display Brinell

hardness value to complete hardness test.

-

Hardness unit

conversion, save test data in group and automatically generate hardness test

report and statement. The test data is stored in the offline database, which

is convenient to check at any time.

-

Precision

conforms to GB/T231.2, ISO 6506-2 and ASTM E10.

It’s suitable to determine the Brinell hardness of unquenched steel, cast iron,

non-ferrous metals and soft bearing alloys, etc.

Specifications

Measuring range:

5-650HBW

Test force: 187.5,

250, 500, 750, 1000, 1500, 3000kgf

(1838.8, 2415.8,

4903.5, 7355.3, 9807, 14710.5, 29421N)

Max. height of test

piece: 950mm (customizable)

Lateral moving

distance of hardness testing mechanism: 650mm

Work table size: 1500

x 1000mm

Maximum moving

distance of work table: 1000mm

Central distance

between two columns: 1350mm (customizable)

Maximum load of work

piece: 4000Kg

Hardness resolution:

0.1 HBW

Power supply: 220V

AC, 50Hz

Dimensions: 2000 x

1500 x 2000mm

Weight: approx.

3000kg

Standard accessories

Main machine: 1 set

Control cabinet: 1

set

Computer: 1 set

Brinell image

measuring system: 1 pc.

Tungsten carbide ball

penetrator: Φ5mm, Φ10mm, 2 pcs. for each

Tungsten carbide

ball: Φ5, Φ10mm, 6 pcs. for each

Brinell standardized

block: 4 pcs.

20X Readout

microscope: 1 pc.

|

|