|

|

MODEL WDW-200D

COMPUTER

CONTROLLED ELECTRONIC

UNIVERSAL TESTING MACHINE

Application

WDW-200D

is widely

used in tensile, compression, bending and shear tests of metal and nonmetal

materials. With a variety of accessories, it can also be used to test the

mechanical properties of profiles and components. It also has a very wide

application prospect in the field of rope, belt, wire, rubber, plastic and other

materials with large sample deformation and fast test speed. It is suitable for

quality supervision, teaching and scientific research, aerospace, iron and steel

metallurgy, automobile, construction materials and other experimental fields.

Standards

It meets the requirements of GB/T

228.1-2010 <<Tensile

test method for metallic materials at room temperature>> and

GB/T

7314-2005

<<Compression

test method for metals>>,

as well as

ISO 7500-1,

ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO6892,

etc. It conforms to the requirement of

data

processing of GB, ISO, ASTM, DIN and other standards.

Main machine structure

The main

machine

adopts double space portal structure, with upper space stretching, lower space

compressing and bending. The crossbeam is stepless lifting. The transmission

part adopts arc synchronous toothed belt, and the lead screw pair drives, with

stable transmission and low noise. The specially designed gear belt speed

reduction system and precision ball screw pair drive the moving beam of the

testing machine to move, realizing no gap transmission.

Accessories

Standard

configuration: a set of wedge

tensile testing attachment and

compression testing attachment.

Electrical measurement and control system

-

Using

stepping motor (AC

servo system and servo motor are

optional),

stable and reliable performance, with over-current, over-voltage, over

speed, overload and other protection devices.

-

It has

the functions of overload, over-current, over-voltage, upper and lower limit

of displacement and emergency stop.

-

The

built-in controller ensures that the testing machine can realize the control

of beam displacement and other parameters, and realize constant velocity

displacement..

-

At the

end of the test, it can return to the initial position at high speed

manually or automatically.

-

The

real physical zero adjustment, gain adjustment and automatic shift, zero

adjustment, calibration and disk saving of test force measurement are

realized without any analog adjustment link, and the control circuit is

highly integrated.

-

Electrical control circuit reference international standards, in line with

the national testing machine electrical standards, strong anti-interference

ability, to ensure the stability of the controller, experimental data

accuracy.

-

With

network interface, it can transmit, store, print and record data, and

connect with intranet or Internet.

Description of main functions and features of the software

The software is used for testing various metals and nonmetals (e.g. wood-based

panel) by microcomputer controlled electronic universal testing machine. It can

complete real-time measurement and display, real-time control and data

processing, result output and other functions according to the corresponding

standards.

-

Sub

authority management, different levels of operators have different operation

authority, the menu can be operated is also different, not only the ordinary

operator operation is simple, convenient, fast, but also effectively protect

the system.

-

Real

time measurement and display of test force, peak value, displacement,

deformation and other signals.

Real-time

acquisition and control under

Windows platforms

such as Win

XP, Win 7 & Win 10, etc.

Accurate

timing and high-speed sampling are realized.

-

The

real-time screen display of load deformation, load displacement and other

test curves is realized, and the observation can be switched at any time.

-

The

computer storage, setting, loading and other functions of test parameters,

zero setting, calibration and other operations are carried out from the

software, and each parameter can be conveniently stored and transferred in,

so that a host with multiple sensors can be easily switched, and there is no

number limit.

-

It

supports the constant velocity displacement control mode, and gives the

standard reference curve in the process of debugging parameters by advanced

operators, so that users can actually observe the influence of various

parameters on the effect.

-

Human

computer interaction was used to analyze the data. The processing method can

meet the requirements of GB/T 228-2010 metallic materials tensile test at

room temperature, which is widely used. It can automatically calculate the

elastic modulus, yield strength, specified non proportional elongation

strength and other performance parameters. It can also manually intervene in

the analysis process to improve the accuracy of analysis. It can also

process other data according to the standards provided by users.

-

The

test data is stored in text file to facilitate users' query, and

reprocessing the test data by using any general commercial report and word

processing software. At the same time, it is convenient to transfer data on

the Internet.

-

It can

record and save the data curve of the whole process of the test, and has the

demonstration function to realize the reappearance of the test curve. It can

also be used for curve superposition and comparison, which is convenient for

comparative analysis.

-

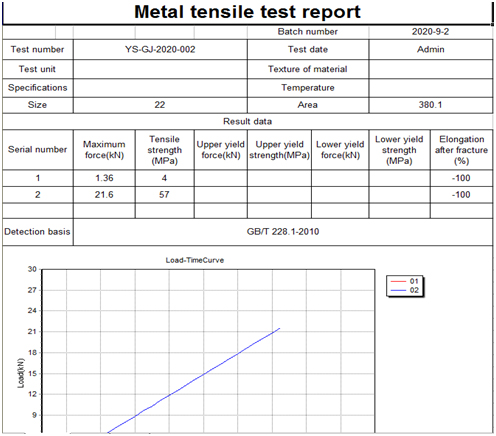

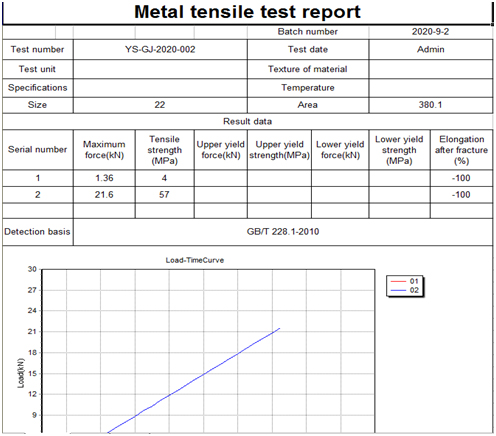

The

test report can be printed in the format required by users. Users can choose

the basic information of report output and the content of test results and

curves to meet various needs.

-

The

digital zero adjustment and automatic calibration of test force and

deformation are realized, which facilitates the operation and improves the

reliability of the machine. All kinds of parameter system settings are

stored in the form of file, which is easy to save and restore.

-

It can

be used in Win

XP, Win 7 & Win 10 and

other operating systems. The control of test process, the change of moving

speed of beam and the input of parameters can be completed by keyboard and

mouse, which is convenient and fast.

-

It can

automatically identify and support external inching control, which makes it

convenient to clamp the sample.

-

With

overload protection automatic stop function, and can automatically judge the

sample fracture, automatic stop.

-

According to different user requirements, the above software functions will

be increased or decreased or adjusted.

Software and software operation interface

1. The software can be used in

Windows XP / Window 7 / Windows 10, and the user interface presents a similar

style as Windows system.

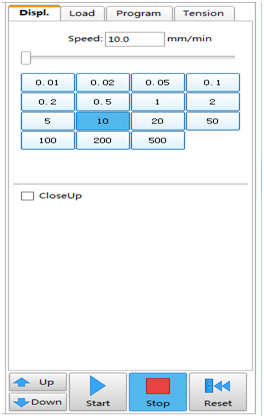

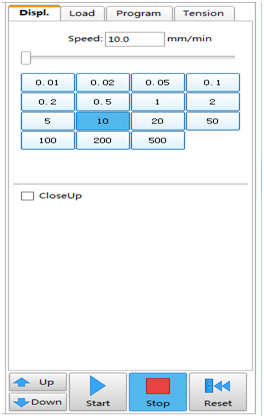

2. Control mode.

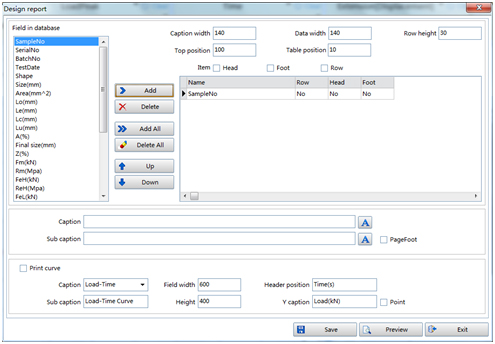

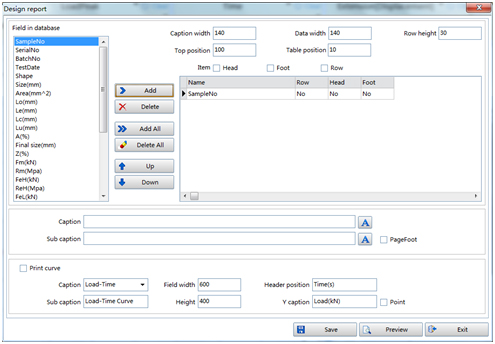

3. Report editor:

4. There are many kinds of test

methods to choose from

5. The software has three levels of

management authority, which are logged in by their respective passwords to

further ensure the safe use of the software.

Main technical specifications:

-

Max

Test Load:

200KN

-

Accuracy level:

Level 1 (Level

0.5 optional)

-

Measurement

range of test force:

less

than 2%

~

100%

F·S (no

grading in the whole

scale)

-

Accuracy

of force value: better

than ± 1% / ± 0.5% of indication

-

Relative

error of test force indication: less

than ± 1%

-

Resolution

of test force:

1/300000 of the max. test

force

-

Deformation measurement range (with large deformation extensometer):

10-1000mm

-

Accuracy

of deformation measurement: better

than ± 1% / ± 0.5% of the indicated value

-

Relative

error of deformation indication: less

than ± 1%

-

Deformation resolution: 1/300000

of the maximum deformation (mm)

-

Displacement

accuracy: better

than ± 1% / ± 0.5% of the indication

-

Relative

error of displacement indication: less

than ± 1%

-

Displacement resolution:

0.001mm

-

Speed

range: 0.001

~ 500mm / min, stepless

speed regulation

-

Speed

accuracy:

less

than ± 1% of the indicated value

-

Tensile space:

600mm (customizable)

-

Compression space:

600mm (customizable)

-

Test

width:

600mm

-

It can be equipped with the

fixtures such

as

tensile,

compression, bending, shearing, peeling, tearing, etc.

-

Overall

dimension of main machine: 1140 x 890 x 2450 mm

-

Main machine net weight:

1400 KG

System configuration

-

Main machine frame:

1 set

-

Deceleration system:

synchronous

toothed belt,

1 set

-

Rolling

ball screw pair: 2 sets

-

Load

sensor:

200KN,

1 pc.

-

Computer:

HP

commercial PC,

1 set

-

Printer:

ink jet

printer,

1 set

-

Software

and control system:

1 set

-

Attached tools, documents,

operation

& installation

manual, etc.:

1 set

-

Standard

accessory:

Wedge tensile

testing attachment, (choose 3 pairs

from the following):

Flat jaw:

0~7mm, 7~14mm, 14~21mm, Round jaw:

Ф 4~9mm,

Ф 9~14mm,

Ф 14~21mm

Compression testing attachment: Pressure plate diameter

Ф 100mm,

1 pair

|

|